What is Electroless Nickel Plating?

Electroless Nickel Plating is a non-electric coating process that deposits a layer of nickel-phosphorus or nickel-boron alloy on metal surfaces. Unlike electroplating, which requires an electric current, electroless nickel plating relies on a chemical reaction to deposit the coating evenly across the entire surface of a part, including complex geometries and hard-to-reach areas. This process produces a uniform, corrosion-resistant, and hard surface that enhances the durability and performance of metal parts. Electroless Nickel coatings are known for their superior wear resistance, excellent lubrication properties, and enhanced solderability. It is widely used in industries such as aerospace, automotive, medical devices, and electronics to improve the lifespan and functionality of components.

Benefits of Electroless Nickel Plating

-

Uniform thickness eliminates the need for machining after plating.

-

Superior corrosion resistance extends component life in harsh environments.

-

High hardness improves wear resistance and reduces friction.

-

Enhanced solderability and lubricity for electronics and mechanical parts.

-

Non-magnetic options available with high phosphorus coatings.

FAQs

Yes, with proper surface preparation, it can coat plastics and non-metal substrates.

Electroless nickel provides more uniform coatings and better corrosion resistance without electricity.

Optional heat treatment can increase hardness but may reduce corrosion resistance.

Typically ranges from 2.5 to 125 microns (0.0001” to 0.005”), with tight thickness control.

Low, mid, and high phosphorus coatings, each with distinct hardness and corrosion resistance.

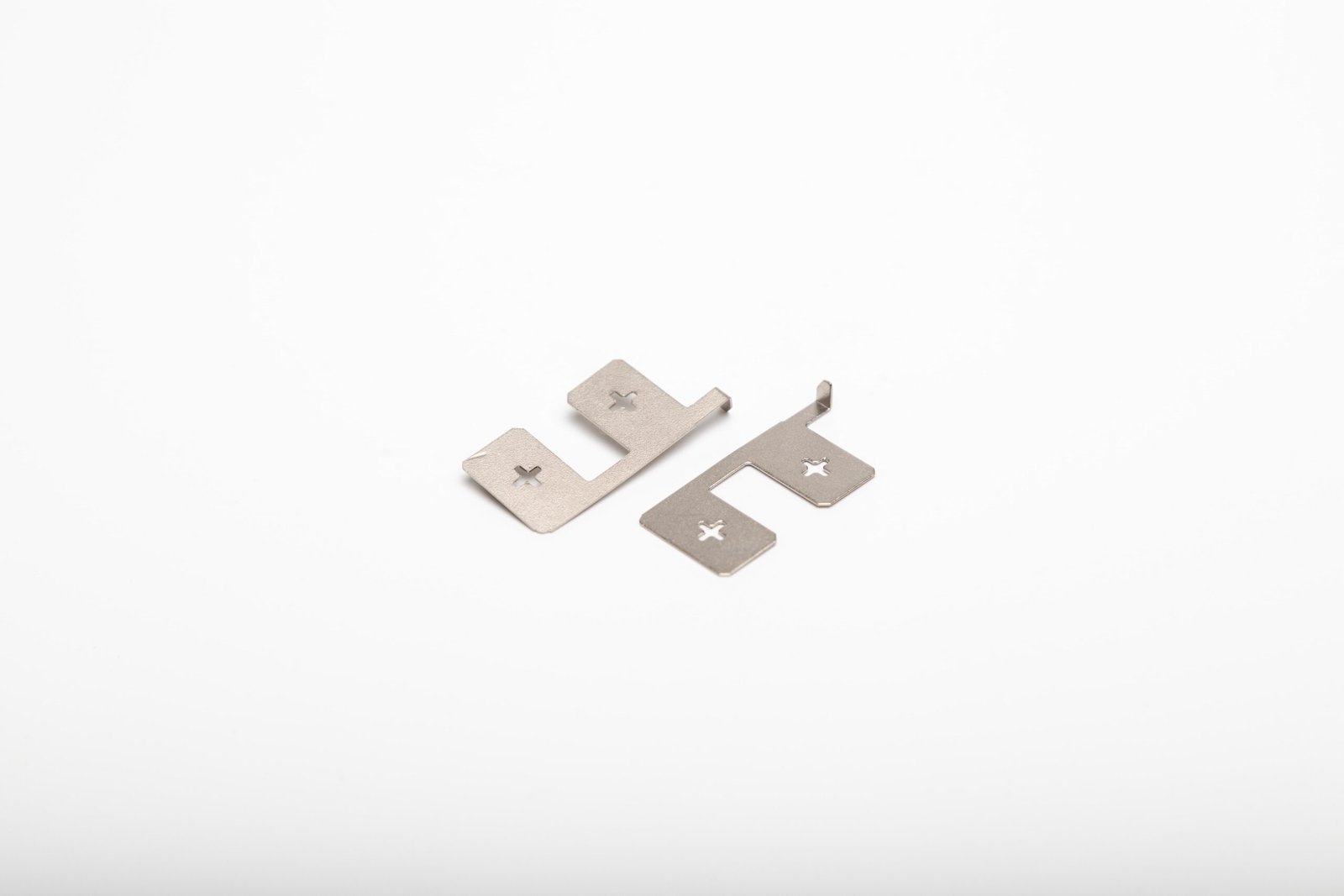

Application Of Electroless Nickel Plating

Electroless Nickel Plating is used for improving wear resistance, hardness, and corrosion resistance on parts that require uniform coating thickness.

Enquire about our services