What is Electroplating and Coating?

Electroplating and coating are processes used to enhance the properties of surfaces, creating functional attributes such as increased corrosion resistance, improved aesthetic, and enhanced properties like conductivity or hardness. These processes are widely used across various industries, from automotive and electronics to jewelry and appliances. Understanding the methodology and applications of electroplating and coating can provide insight into their importance in modern manufacturing and design.

How does electroplating work?

Electroplating is an electrochemical process wherein metal ions in a solution are deposited onto a substrate material, typically an object. This process not only enhances the surface characteristics of the substrate but also allows for the creation of intricate designs and finishes that would be otherwise difficult to achieve through traditional machining or casting methods.

Applications of Electroplating In Various Industries

Automotive Industry

Electroplating is used to coat components like gears, brake parts, and fasteners to improve wear resistance, reduce friction, and protect against corrosion, ensuring the longevity and reliability of parts.

Electronics Manufacturing

Electroplating enhances the conductivity and corrosion resistance of connectors, switches, and circuit boards, ensuring better performance in electronic devices.

Tool Manufacturing

Cutting tools, drills, and dies are electroplated with hard metals like chromium to increase their hardness, durability, and resistance to wear and corrosion, ensuring better cutting performance and longevity.

Energy Sector

Components like turbine blades, electrical contacts, and connectors are electroplated to enhance their resistance to corrosion and wear, improving efficiency and durability in power generation systems

Oil and Gas Industry

Electroplating helps protect critical equipment such as valves, pumps, and pipelines from corrosion, ensuring they can withstand harsh environmental conditions and extend service life.

Household Appliances

Parts like faucets, knobs, and other hardware are electroplated to provide a sleek finish and protect against rust, wear, and tarnishing, enhancing both the aesthetics and functionality of the products.

Marine Industry

Electroplating is essential for parts exposed to saltwater environments, such as boat fittings, propellers, and other marine components, as it offers excellent protection against corrosion.

Aerospace and Defense

Aircraft components, such as landing gears, turbine blades, and fasteners, benefit from electroplating to improve resistance to corrosion, wear, and high temperatures, ensuring operational safety.

Medical Devices

Electroplating is used to enhance the performance of medical instruments like surgical tools and implants by providing a smooth, durable, and biocompatible surface that resists corrosion and wear.

Jewelry and Decorative Products

Electroplating is commonly used in the production of jewelry to add a high-quality finish with a shiny appearance while also providing a protective layer to prevent tarnishing and wear.

Our Services

We specialize in high-quality metal surface finishing solutions.

We offer a comprehensive range of metal surface finishing services designed to enhance the durability, performance, and aesthetic appeal of metal components.

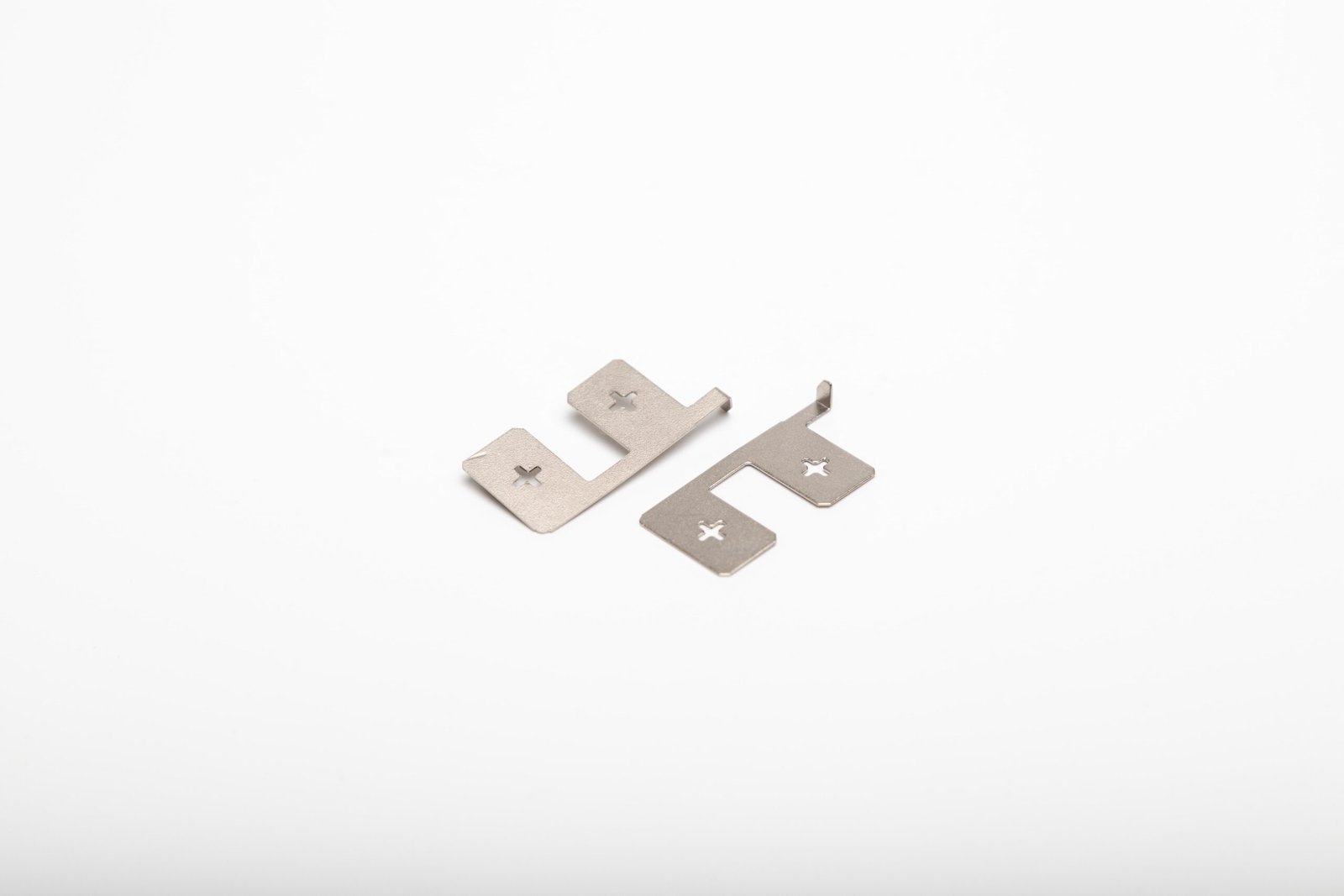

Zinc Nickel Plating

Fukar specializes in professional zinc nickel plating services in Malaysia, delivering superior corrosion protection for automotive, aerospace, and industrial components. Our advanced zinc-nickel electroplating process provides exceptional durability with 10-15 micron coating thickness and over 720 hours of salt spray resistance, meeting strict automotive industry standards. As an ISO-certified metal plating company, we serve Malaysia’s leading manufacturers with reliable, high-quality zinc-nickel plating solutions that extend component life and reduce maintenance costs. From precision automotive parts to critical aerospace components, our zinc nickel plating services in Malaysia ensure your products meet the most demanding performance requirements while maintaining cost-effective production schedules.

Zinc Flake Coating

Fukar delivers professional zinc flake coating services in Malaysia, providing advanced corrosion protection for automotive and industrial fasteners operating in extreme environments. Our zinc flake coating process applies ultra-thin, uniform layers that deliver superior salt spray resistance exceeding 1000 hours while maintaining precise dimensional tolerances essential for high-strength bolts, nuts, and critical fasteners. As Malaysia’s specialized coating services provider, we serve automotive manufacturers, wind energy, and heavy machinery industries with zinc flake coating solutions that eliminate hydrogen embrittlement risks while providing exceptional corrosion performance. Our expert application ensures your components meet stringent automotive specifications including GM, Ford, and European OEM standards for coating durability and environmental compliance.

Xylar / Xylan Coating

Fukar provides professional Xylan and Xylar coating services in Malaysia, offering advanced PTFE-based industrial coatings for extreme operating conditions. Our Xylar coating solutions, including Xylar-2 and Xylar 101, deliver exceptional non-stick properties, chemical resistance, and temperature stability from -70°C to +260°C, making them ideal for automotive, oil and gas, and manufacturing applications. As Malaysia’s trusted coating services provider, we apply these premium fluoropolymer coatings to valves, pumps, fasteners, and critical industrial components that demand superior wear resistance and low-friction performance. Our expert Xylan coating services ensure your equipment operates reliably in harsh environments while reducing maintenance requirements and extending operational life.

Zinc Flake Coating

If you’re looking for a premium inorganic coating, Zinc Flake Coating is what you need. Comprised of zinc or zinc aluminium flakes, it has excellent corrosion resistance and is affordable.

Zinc Nickel Plating

(ASTM B841)

Looking for superior corrosion protection? Then Zinc Nickel Plating is what you’re looking for.

Zinc Plating

(ASTMB633, TSG6524G, MS82-3701)

Zinc Plating creates a physical layer that acts as a barrier to prevent rust from reach the underlying metal surface.

Electroless Nickel

Electroless nickel is a chemical process that deposits an even layer of nickel-phosphorus or nickel-born alloy on metal surfaces.

Phosphating

Phosphating is a conversion coating that is applied via immersion. It chemically reacts with a surface to form a layer of insoluble crystalline phosphate.

Stainless Steel Passivation

Stainless steel passivation is a critical chemical treatment process that significantly enhances corrosion resistance and surface quality of stainless steel components by creating a protective oxide layer. Its precision and reliability make it an indispensable solution across industries where sterility and chemical resistance are paramount.

Aluminium Passivation

Aluminium passivation is a specialized surface treatment process that dramatically improves corrosion protection and durability of aluminium components while maintaining their lightweight characteristics