Electronics Protection Coating

In the electronics industry, precision, reliability, and performance are fundamental requirements that define product quality and consumer trust. Electronic devices and components operate in diverse environments—from humid tropical climates to dry desert conditions, and from temperature-controlled data centers to portable devices exposed to daily handling. Metal components in electronics are particularly vulnerable to corrosion, which can cause circuit failures, signal degradation, and complete device malfunction. Protecting metal surfaces from corrosion is essential for ensuring product longevity, maintaining performance standards, and meeting quality expectations. Zinc plating has become a widely adopted solution in electronics manufacturing due to its excellent protective properties and compatibility with sensitive electronic components.

The Critical Need for Metal Protection in Electronics

Corrosion in electronics occurs when metal components react with atmospheric moisture, oxygen, contaminants, and electrolytes, leading to oxidation, tarnishing, and material degradation. Even minor corrosion can disrupt electrical conductivity, increase resistance, and cause intermittent failures that are difficult to diagnose.

For the electronics industry, metal surface protection is critical for the following reasons:

Guaranteeing Consistent Device Performance

Corroded connectors, contacts, and circuit board components can cause intermittent failures or complete device malfunction, damaging brand reputation and customer satisfaction.

Preserving Electrical Signal Quality

Corrosion increases electrical resistance and can introduce signal noise, affecting the performance of sensitive electronic circuits and communication systems.

Maximizing Electronic Device Longevity

Protected components resist environmental degradation, allowing electronic devices to function reliably throughout their expected service life.

Minimizing Product Returns and Repairs

Corrosion-related failures are a common source of warranty returns. Effective protection reduces these claims and associated costs.

Achieving Industry Compliance and Certification

Electronics manufacturers must comply with rigorous quality standards and reliability testing protocols, where corrosion resistance is a key performance indicator.

How Zinc Plating Protects Electronic Components

Among the various metal finishing processes available, zinc plating has proven particularly effective for electronics applications due to its protective capabilities, cost-effectiveness, and processing compatibility. Zinc plating involves depositing a thin, uniform layer of zinc onto metal surfaces through an electroplating process. Here’s why zinc plating is so effective for electronics:

Zinc’s Sacrificial Corrosion Mechanism

Zinc’s electrochemical properties make it more reactive than most base metals used in electronics. When exposed to corrosive conditions, zinc corrodes preferentially, protecting the underlying metal from oxidation and degradation.

Creating a Protective Physical Barrier

Zinc plating creates a continuous barrier layer that prevents moisture, oxygen, and atmospheric contaminants from reaching the base metal surface, significantly reducing corrosion rates.

Zinc’s Automatic Repair Capabilities

When zinc plating is scratched or abraded, it forms protective zinc oxide compounds that continue to shield the exposed area, maintaining protection even when the coating is compromised.

Precision Coating for Optimal Protection

Electroplating allows precise control over coating thickness, ensuring optimal protection without affecting the dimensional tolerances critical in electronics manufacturing.

Improving Electrical Connection Quality

Zinc plating can improve solderability of components, facilitating reliable electrical connections during assembly processes.

Common Uses of Zinc Plating in Electronics

Zinc plating is extensively used to protect various electronic components and assemblies, ensuring performance and durability across diverse applications. Below are some examples of its uses:

Protecting Electrical Connection Points

Electrical connectors, terminals, and pins are zinc-plated to prevent corrosion while maintaining excellent electrical conductivity and connection reliability.

Protecting Assembly Components

Screws, nuts, bolts, and mounting hardware used in electronic assemblies are zinc-plated to resist corrosion without interfering with electromagnetic performance.

Protecting Structural Housing Components

Metal housings, brackets, and structural components in computers, telecommunications equipment, and consumer electronics benefit from zinc plating for corrosion protection.

Protecting Thermal Management Systems

Thermal management components are often zinc-plated to resist corrosion while maintaining heat dissipation efficiency.

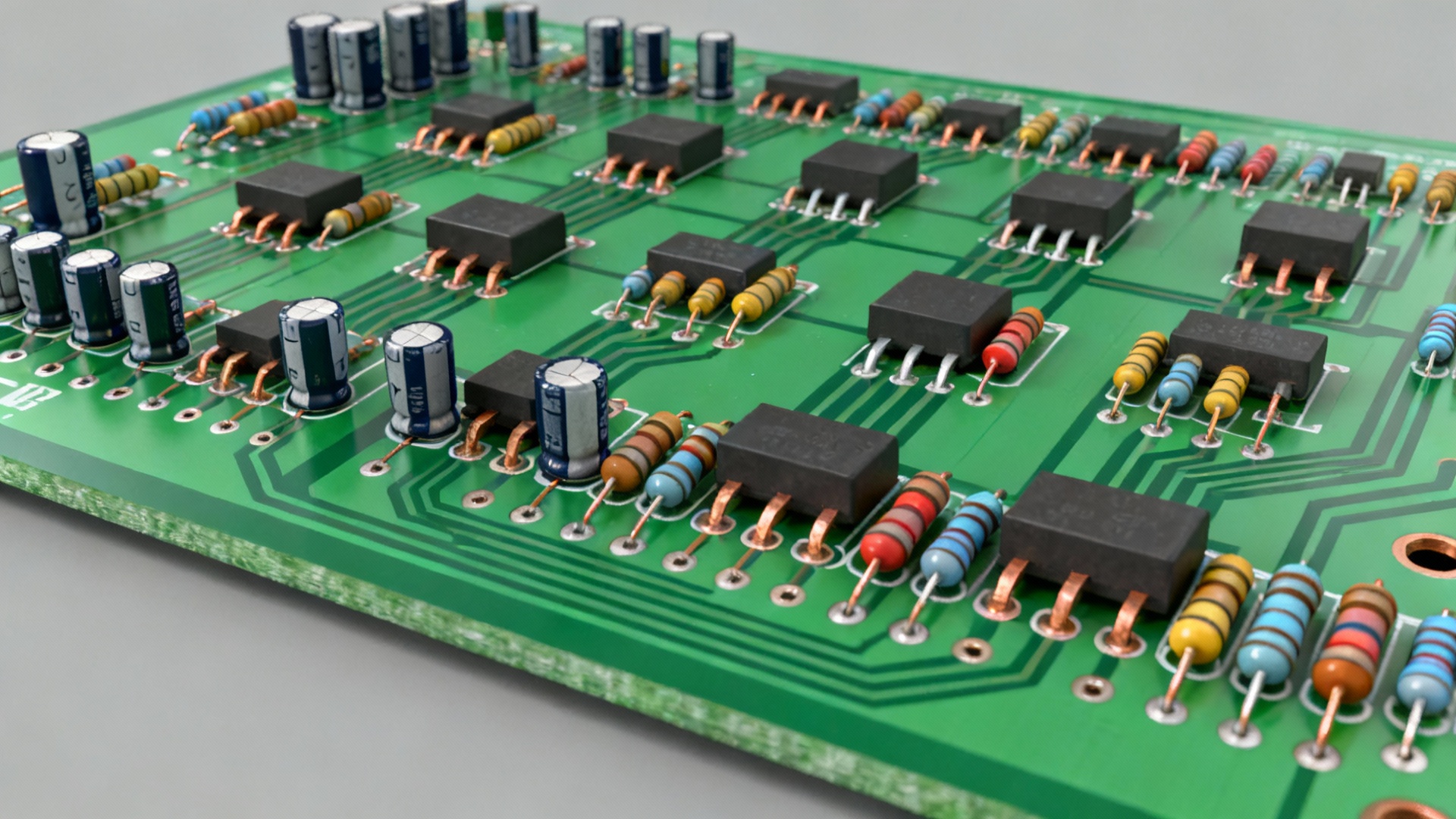

PCB Hardware and Shielding Protection

Selected circuit board hardware and shielding components utilize zinc plating to protect against environmental corrosion while maintaining electrical performance.

Advantages Across the Value Chain

For Consumers:

- Enhanced device reliability and longer operational life.

- Reduced risk of premature device failure due to corrosion.

- Better performance consistency over time.

- Improved value retention and resale potential.

For Manufacturers:

- Compliance with international quality and reliability standards.

- Reduced warranty costs and customer service issues.

- Enhanced brand reputation for producing durable, reliable products.

- Competitive advantage through improved product longevity and performance.

As the electronics industry continues to evolve with miniaturization, higher performance requirements, and expansion into harsh-environment applications such as automotive electronics and IoT devices, the demand for effective corrosion protection methods like zinc plating will continue to grow. Emerging trends in green electronics and sustainability are also driving innovation in environmentally friendly plating processes. By investing in advanced corrosion protection solutions, electronics manufacturers not only enhance product quality but also build customer trust and ensure long-term market success in an increasingly competitive global marketplace.

How we can help

Fukar delivers advanced electroplating and metal coating solutions, including Xylan, Xylar, zinc, nickel, and anodising, to enhance durability, corrosion resistance, and aesthetics for global industrial applications

Enquire about our services